PAB Series - PES Pleated Filter Cartridges

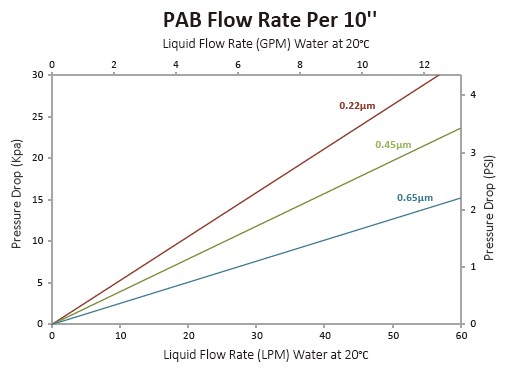

PAB series polyethersulfone (PES) pleated filter cartridges are made of hydrophilic high asymmetric polyethersulfone membrane, which can provide exceptionally high flow rate and long service life for processing large fluid volumes.

PAB series polyethersulfone (PES) pleated filter cartridges are made of hydrophilic high asymmetric polyethersulfone membrane, which can provide exceptionally high flow rate and long service life for processing large fluid volumes. It has excellent retention of microor-ganisms for superior protection of final filters. This characteristic makes it especially suit for suits for Food and Beverage filtration.

Features

- Broad PH compatibility allows the use of filters in a wide range of fluids

- Bioburden reduction efficiency for process with variable bioburden applications with high flow requirements

- 100% integrity tested

- Low extractables

Applications

- Food and beverage

- Reduce bioburden

- High flow process requirements

- Protection of final filters or downstream equipments and systems such as tangential chromatographic

| Dimension | |

| Outer Diameter | 69mm(2.72") |

| Length | 5”, 10”, 20”, 30”, 40” |

| Material of Constructions | |

| Media | PES |

| Support | PP |

| Cage/Core/End cap | PP |

| Connection Adaptor | SS Insert, PSU Insert |

| Seal Material Options | Silicone, EPDM , FKM |

| Operating Conditions | |

| Max. Operating Temperature | 80℃(176℉) |

| Max. Operating DP | 4 bar(58psi)@20℃(68℉),2 bar (29 psi)@80℃(176℉) |

| Sterilization | |

| Autoclave Sterilization | 125℃(257℉), 30min, 30cycles |

| SIP | 125℃(257℉), 30min, 30cycles |

| Filtration Area | 0.65 m² per 10” Filter |

| Extractables | |

| 10” Filter Cartridges | <20mg |

Quality

- Validated with Brevundimonas diminuta (ATCC 19146) at107/cm2 (0.22μm).

- Each membrane filter element has been individually tested for integrity.

- Individual element is tracked by serial number. Manufactured according to ISO 9001:2015 certified quality management system.

- Meets USP Biological Reactivity Test requirements of the current USP <88> for plastic class Ⅵ-121℃.

Effluent quality

- Non-fiber releasing

- Non-pyrogenic per USP Bacterial Endotoxins(<0.25EU/mL)

- Meets TOC and water conductivity per USP Purified Water, pH per USP Sterile Purified Water.

Integrity Test

Order Information

catalog

Recommended Products

Recently Viewed Products

×

Download the documents after filling the form

- *Full Name:

- *Company:

- *Country:

- *Email Address:

- *Phone#: