HIGH FLOW FILTRATION SYSTEMS

Darlly High Flow Filtration system are styled on the design of corrosion resistant FRP pressure vessels. These provide considerable reduction in capital investment versus stainless steel construction and make use of a quick-acting closure.

Darlly High Flow Filtration system are styled on the design of corrosion resistant FRP pressure vessels. These provide considerable reduction in capital investment versus stainless steel construction and make use of a quick-acting closure. Each vessel has the convenience of one Flter element that can be exchanged in seconds.

High Flow Filter elements are available in both polypropylene and glass micro-Fiber media in ratings of 0.5 to 100 microns, and in both nominal and absolute retention performance. The unique layered construction provides excellent retention across a wide range of ow rates. Each six inch diameter 60” length cartridge can handle flow rates of up to 500gpm with the inside-to-outside flow path allowing for high contaminant holding capacity. Superior flow and long filter life make Darlly HighFlow filters an ideal choice for a wide variety of critical process filtration applications.

The innovation of advanced German pleating technology allows the Filter elements to offer higher surface area resulting in superior flow and media utilization. With a tapered pore structure and fine fiber denier, the result is better dirt holding capacity, low resistance to flow, superior filter performance and overall better value for the user.

The inside-to-outside flow configuration and core-less construction of the Darlly HighFlow filter element allows it to be tightly compacted to minimize disposal costs. Maintenance requirements and production downtime is dramatically reduced in comparison with conventional depth filters. Service personal will and it easy & convenient remove used elements since all solid contamination is trapped inside of the lter cavity.

Features(HIGH FLOW FILTER CARTRIDGES)

| High Flow Capacity per Cartridge (vs. Conventional 2.5” Diameter Cartridges) |

Less cartridges are required, therefore:

|

|

Advanced Pleat Design using |

|

|

Compact Design |

|

|

Easy to Operate |

|

|

Safe Materials of Construction |

|

Features(HIGH FLOW FILTER HOUSINGS)

| FRP - GRP housings |

|

|

HighFlow Housing Capability |

|

|

IMP- Replacements & Damages |

|

|

Ease of Use versus conventional |

|

|

Capacity Scaling |

|

|

Reducing capacity |

|

|

Flexible Design Porting |

|

|

Victaulic grooved ends |

|

|

Corrosion-Free Construction |

|

CARTRIDGE SPECIFICATIONS

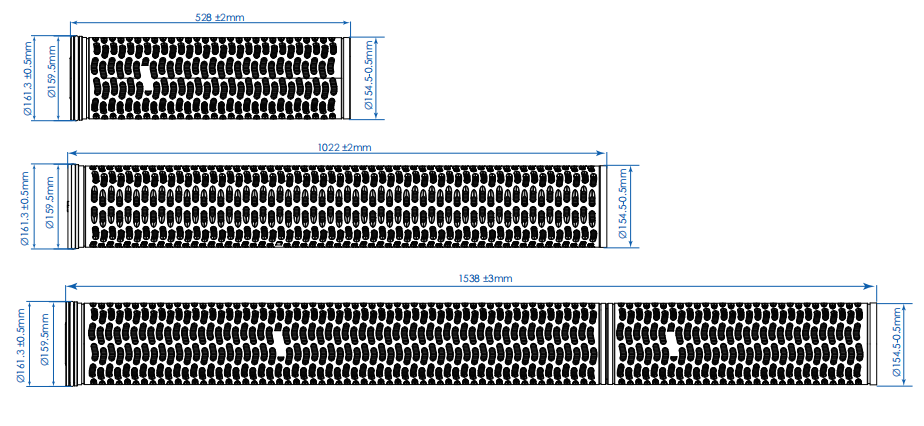

CARTRIDGE DIMENSIONS

| Outside Diameter |

6” |

|

Length |

20”(528mm) 40”(1022mm) 60”(1538mm) |

CONSTRUCTION

| Micron Ratings |

0.5,1, 3, 5, 10, 15, 20, 40, 70,100 |

| Filter media, end caps, outer sleeve |

Polypropylene |

|

Sealing o-ring options |

Silicone,EPDM,NBR,Viton |

OPERATING CONDITIONS

| Maximum recommended flow rate in water (@20° C) |

50m³/h for 40" filter |

| Maximum continuous operating temperature |

70°C |

|

Maximum hot water sanitisation temperature |

90°C |

|

Maximum forward differential pressure 3.4 bar @ 20°C |

3.4 bar @ 20°C |

|

Recommended change-out differential pressure |

2.4 bar @ 20°C |

HOUSING SPECIFICATIONS

SPECIFICATION

|

FILTER HOUSING

|

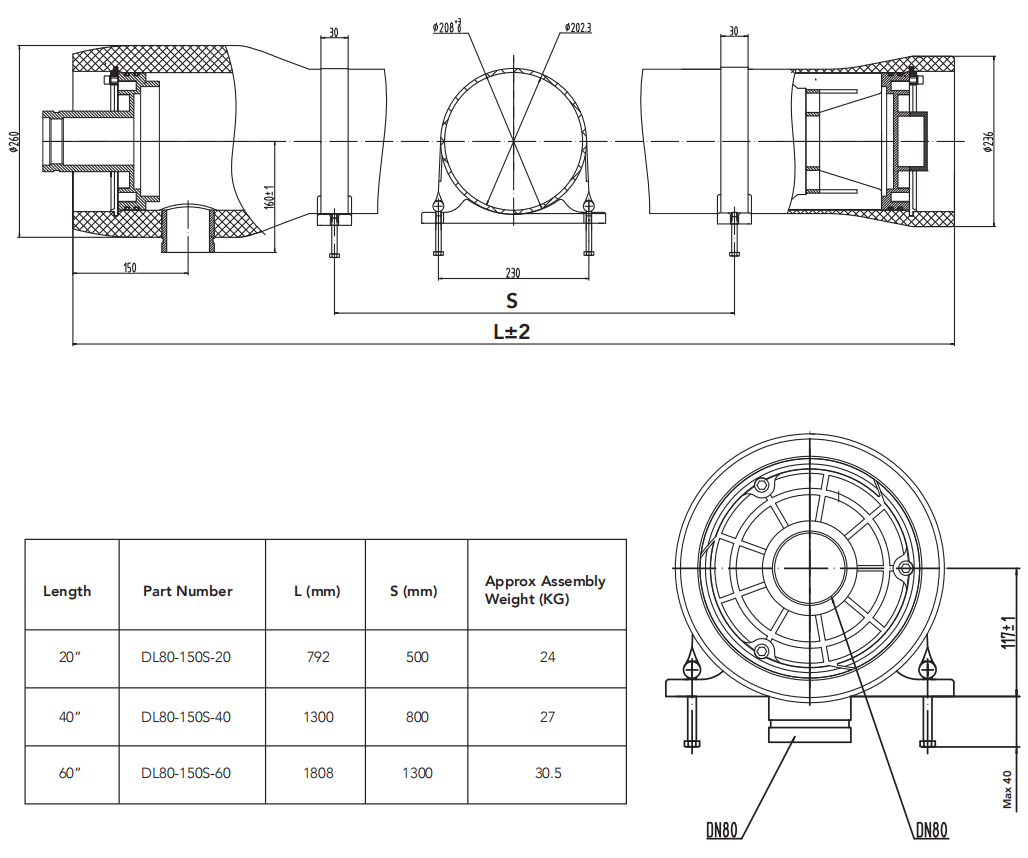

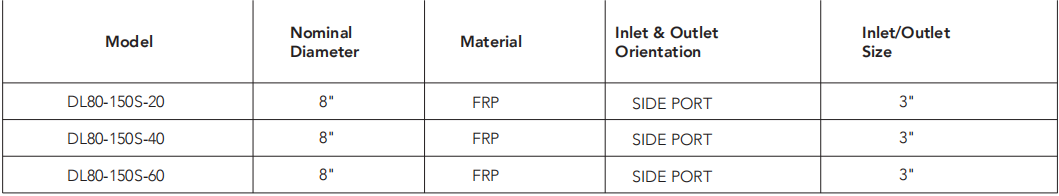

Dimensions

|

|

|

Order Information

|

Download Catalog

- *Full Name:

- *Company:

- *Country:

- *Email Address:

- *Phone#: