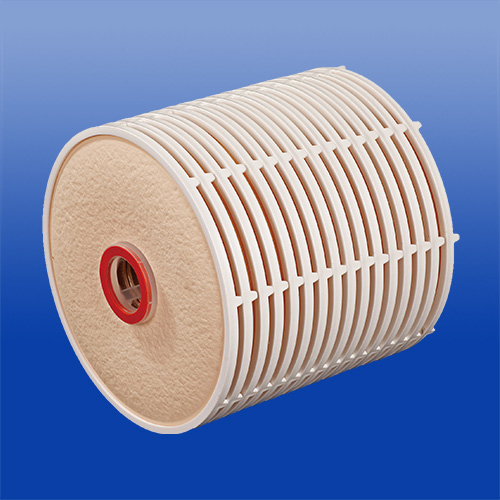

BDS series -Depth Stack Filter Cartridge

The BDS series of deep-layer membrane reactor filter elements are composited with high-purity lignocellulose and inorganic filter aids (diatomaceous earth, etc.). Its special three-dimensional space channel enables thousands of square meters of internal s

The BDS series of deep-layer membrane reactor filter elements are composited with high-purity lignocellulose and inorganic filter aids (diatomaceous earth, etc.). Its special three-dimensional space channel enables thousands of square meters of internal surface area per square meter of filtration area. With extremely high dirt holding capacity and filtering quality, diatomaceous earth and resin can not only improve the permeability of the filter plate, but also improve the overall adsorption of the filter plate. It can prevent impurities and impurities in the liquid through mechanical interception, static adsorption, etc. The microorganisms are effectively filtered, and the deep stacking process effectively solves the problems of material and liquid loss, large workload, and high investment cost of traditional plate and frame filters.

Features

| • It can be washed under certain conditions to extend the service life • The operation is simple and reliable, and the solid outer frame design prevents the filter element from being damaged during installation and disassembly • Heat disinfection or hot filter fluid has no adverse effect on the filter board |

Applications

| • Biopharmaceutical • Fine Chemicals • food and drink |

Quality

| • The filter elements are produced in 100,000 grade clean environment • Strictly implement THE ISO9001:2015 quality management system • All filter core materials and components are made of FDA-certified materials |

catalog

- *Full Name:

- *Company:

- *Country:

- *Email Address:

- *Phone#: