PTG Series - Sterilizing Filter Cartridges

PTG Series Filter Cartridges feature hydrophobic polytetraflu-oroethylene (PTFE) membrane which offers excellent chemical compatibility and is an ideal choice as an air/gas vent filter. Specialty-grade polypropylene hardware and support layers offer enhan

PTG Series Filter Cartridges feature hydrophobic polytetraflu-oroethylene (PTFE) membrane which offers excellent chemical compatibility and is an ideal choice as an air/gas vent filter. Specialty-grade polypropylene hardware and support layers offer enhanced resistance to oxidation. Is well-suited as an air vent filter for fermentation processes. Integrity testable by water intrusion (WIT).

Features

- Absolute 0.2µm filtration efficiency.

- 100% integrity tested.

- Receives a final rinse with 18MΩ ultrapure water to assure cleanliness.

- Excellent chemical compatibility. Tolerates pH 1 to 14. Hydrophilic membrane resists wetting.

Applications

- Sterile process air

- Aseptic packaging

- Tank air vents

- Fermentation process feed air

- Compressed gases

- Tolerates aggressive fluids: solvents, strong acids, & bases

Specifications

| Dimensions | |

| OD | 69mm (2.72”) OD |

| Lengths | 5”, 10”, 20”, 30”, 40” |

| Filtration Area |

0.8m² per 10” filter |

| Materials of Construction | |

| Media | Inherently hydrophobic PTFE |

| Support Layers | Polypropylene |

| Cage/Core/End Caps | Polypropylene |

| Seal Material Options | Silicone, EPDM, FKM |

|

Removal Efficiency |

|

| 0022 |

Gas: 0.01μm Liquid: 0.2μm |

| Operating Limits | |

| Max. Temperature | 80° C (176° F) |

| Max. dP (forward) |

4 bar (60 psi) @ 20°C (68°F) 2.4 bar (35 psi) @ 80°C (176°F) |

| Sterilization |

0.3 bar (5 psi) @ 142°C (288°F) for 30 minutes by SIP 0.5 bar (7.5 psi) @ 135°C (275°F) 1.0 bar (15 psi) @ 125°C (275°F) |

Quality

- Individually tested for integrity.

- Filter cartridges are manufactured in a clean room environ- ment using Good Manufacturing Practices under an ISO9001:2015 registered Quality Management System.

- Cartridges are individually serialized and have full materials traceability.

Integrity Test Parameters

| Bubble Point (BP) | ≥1.1Bar@IPA: Water 60:40 |

| Diffusion Flow (DF) | PTGP≤16ml / min@1035mbar |

| PTGW≤24ml / min@1035mbar | |

| Water Instrusion (WIT) | PTGP≤0.38ml / min@2500mbar |

| PTGW≤0.75ml / min@2500mbar |

Food Contact Safety

- Materials of construction comply with USFDA regulations for safe use with food and beverages.

- Materials used in the production of the media and hardware meet specifications for biological safety in accordance with USP Class VI – 121°C for Plastics.

- Complies with European Directive EC1935/2004.

- Halal certified.

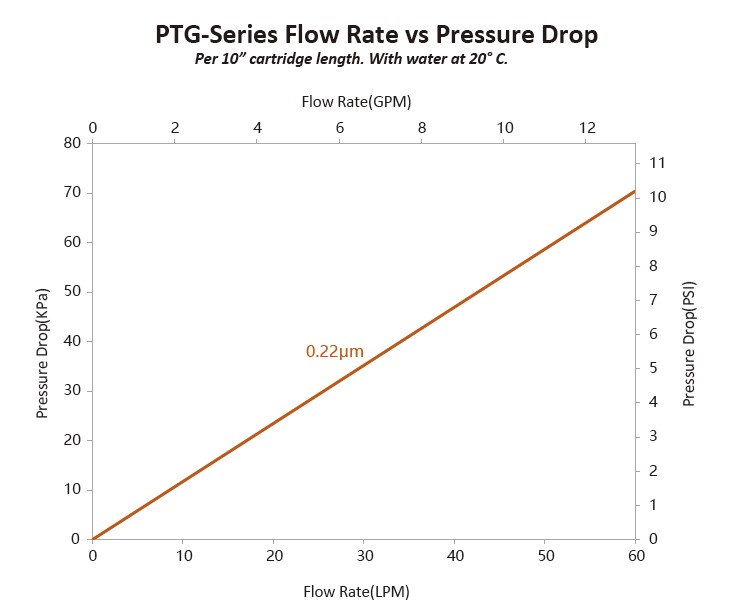

Flow Rate vs Pressure Drop

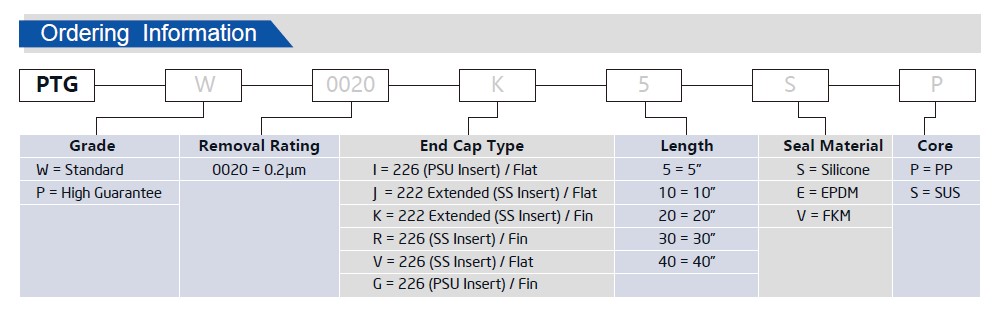

Ordering Information

catalog

- *Full Name:

- *Company:

- *Country:

- *Email Address:

- *Phone#: