Beer Filtration

About 6000 years ago, the Sumerians discovered a cheerful drink, beer, which became popular all over the world. In order to maintain the unity of beer flavor, freshness and quality, the membrane filtration process needs to firmly control microorganisms and organic matters, clarify, and better vision. Darlly Filtration has more than 20 years of development and manufacturing experience, combined with the laboratory can provide Microbiology and validation services to ensure that the products provided are stable and efficient. Beer is a kind of low alcohol fermented wine with malt and water as main raw materials and hops (including hops products) fermented by yeast. Note: including non alcohol beer (dealcohol beer). According to the industry development and consumption demand, it is mainly divided into: cooked beer, draft beer and fresh beer. Cooked beer is pasteurized or instant high temperature sterilized beer. Draft beer is a kind of beer without pasteurization or instantaneous high temperature sterilization, but using other physical methods to eliminate bacteria and achieve certain biological stability. Fresh beer is a kind of beer without pasteurization or instantaneous high temperature sterilization, and a certain amount of live yeast is allowed in the finished product to achieve certain biological stability.

Wine Filtration

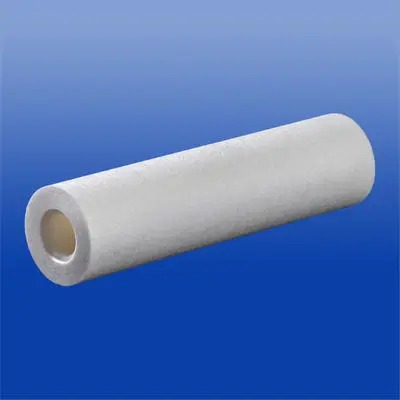

The taste of wine is an organic combination of technology and art. Filtration technology plays a vital role, such as particles, crystals, residues, organic matter, bacteria and yeast microorganisms, etc., which always affect the body, but with a delicate balance, the whole process control is the best solution. Many years of development and manufacturing experience combined with laboratory verification and analysis services, we bring together every solution and product, and apply it to the brewing process, so that customers can get full-bodied wine with pure taste and unique style. Ripe grape string is the main raw material of winemaking, good wine, the craft is equally important. The brewing process represents as much potential quality as possible in the raw material, and is economical and perfect in the wine. Wine features: 1. SO2 plays an anti-oxidation and fresh-keeping role from picking, pressing, fermentation, ripening to bottling. SO2 (usually potassium metabisulfite K2S2O5) is also added to wine as a protective agent and antioxidant, which can kill bacteria while protecting the natural fruit properties of the wine and preventing aging. 2. Tartaric Acid, whose scientific name is 2, 3-dihydroxysuccinic Acid, is derived from grape fruits. Its physical properties make it easy to crystallize at low temperatures and produce insoluble calcium salts, etc. Filtration applications in wine production 1. Clarification and filtration: generally, diatomite filter and paperboard are used for filtration, or the tangential flow filtration system of hollow fiber is adopted. 2. Remove tartarate crystal (potassium tartarate, calcium tartarate) and other particles, PP melt spray or fold filter core, 2-3 m nominal accuracy, 10 m absolute accuracy. 3. Wine recovery: solid-liquid separation system, such as plate and frame filter press, is adopted. 4. Pre-filtration before bottling: PP or GF folding filter element, 0.2-0.45 m nominal accuracy, 1 ~ 2 m absolute accuracy. 5. Sterilizing filtration before bottling: PES/N66/PVDF membrane filter element, 0.45 ~ 0.65 m. 6. Process and bottle washing water filtration: PP large-flow folding filter element with 40 m absolute accuracy, PP folding /GF folding/N66 film/hydrophilic PVDF film /PES film filter element with 0.45 ~ 1.5 m absolute accuracy. 7. Sterilization and filtration of process gas: hydrophobic PTFE membrane filter core, 0.22 m, up to 0.01 m in gas. Note: For detailed technical solutions, please contact your sales engineer. Examples of red wine brewing techniques:

Soft Drinks Filtration

Soft drinks have become a mainstream commodity in People's Daily consumption. However, due to the change of people's consumption concept towards health and safety and the stricter supervision standards of the soft drinks industry implemented by the state, product adjustment and process equipment upgrading are imminent. Darlly filtration solutions and products cover the standard required for filtration and separation of soft drinks to help customers ensure product compliance, nutritional beauty and maintain unique flavor. The main raw materials of soft drinks are drinking water, extracts of roots, stems, leaves, flowers and fruits of plants, concentrated liquid, food additives including sweeteners, sour agents, flavors, fragrances, food coloring stabilizers and preservatives, and some add certain gases (nitrogen, carbon dioxide, etc.) to enrich the taste and product experience. In the production process, sterilization, particle and impurity interception, accurate clarification, etc. involved in the process will have an impact on the final product quality, so it is very important to select the appropriate filtration products.

Dairy Products Filtration

With the rapid development of economy and the change of people's living and eating habits, the production, supply and sales of dairy products show a rapid growth trend, and the market competition is increasingly fierce. The filtration and separation, degreasing, concentration, sterilization and other processes of dairy products should meet the dual requirements of product safety and maintaining nutritional value.Darlly Filtration has more than 20 years of experience in development and manufacturing and excellent technical service team to help customers cope with the consumption upgrade and product structure adjustment of dairy products. In 2008, China's dairy industry experienced the havoc caused by the melamine incident, which made the industry feel bitter and ushered in a vigorous reform. Today, a modern food manufacturing industry with the world's advanced level is unfolding in front of the world. China's raw milk, fresh milk quality and technical equipment of dairy processing enterprises have reached the world's advanced level.Milk is a paradise for microbial activity. The advanced filtration equipment and technology plays an indispensable role in the equipment upgrade, product quality stability and variety updating of the dairy industry.

Cooking Oil Filtration

Darlly Filtration wool oil filtration and multi-stage precise edible oil filtration solutions solve the problems of soybean, peanut, rapeseed, castor oil and other machine-pressed wool oil in oil industry, such as difficult filtration and difficult residue discharge, especially suitable for decolorizing, polishing and filtering, clarifying and filtering, crystal filtration and other processes in oil production. Soybean oil, peanut oil and sesame oil are the major oils in China, and their fatty acid compositions are mainly oleic acid and linoleic acid, which are the main edible oils for human beings. The content of free fatty acid is less than 2% in general, and can reach the quality of ordinary edible oil after crude refining. But will contain a very small amount of impurities, impurities, although less impact. To be filtered:Suspended impurities: sediment, embryo powder, cake residue; Moisture.Colloidal impurities: phospholipids, proteins, sugars and lower decomposition products;Lipid-soluble impurities: free fatty acids, sterols, tocopherols, pigments, fatty alcohols, waxes;Other impurities: toxins, pesticides.

Juice Filtration

Juice -In the production of fruit juice, the retention of flavor and nutrition is the bottleneck restricting the development of the industry. Membrane filtration process is carried out at room temperature with mild filtration, which helps to retain the original taste of raw materials and remove bacteria, spores, colloid and peculiar smell and bitterness, etc. It is a promising sterilizing and clarifying technology for juice drinks. Because the raw materials contain products that block the filter material, Darlly Filtration has rich experience in selecting appropriate filter products. Fruit juice is a fermentable but unfermented juice or serous product made from fruits or vegetables using physical methods (mechanical methods, water extraction, etc.). Or in concentrated fruit juice (pulp) added to the same amount of water removed during processing to restore the juice, slurry products. The membrane filtration process is carried out at room temperature, does not involve heating process, and does not change the flavor and nutritional ingredients of the product, especially the heat-sensitive ingredients, making it an excellent choice for fruit juice and its drinks.

Fructose Syrup Filtration

Fructose syrupHigh fructose corn syrup is an important natural sweetener, and its functionality and economy make it an ideal substitute for granulated sugar. During the production process of HFCS, temperature, viscosity, density and so on have higher requirements on the precision, strength, filtration efficiency and reuse of filtration materials. Syrup from the variety of products and impurities in the process of production the whole filtration process involves clarifying protection filter, remove the insoluble protein, mechanical impurity, activated carbon capture and eventually eliminate bacterium, Darlly Filtration big set according to the requirements of fructose syrup each process point design the most appropriate filtering solution for your product to achieve the best filtering effect, while keeping the economy. High fructose corn syrup (HFCS), a new product developed in the 1970s, is an important sweetener. It is a kind of mixed syrup made from starch in rice, corn and potato, which is liquefied by -amylase, hydrolyzed by glycosylase and converted into glucose, and then isomerized by glucose isomerase. It is mainly composed of fructose and glucose.Fructose syrup has high temperature, high sugar content and certain viscosity in the production process. The accuracy and efficiency of filtration materials, product strength and recoverability of filtration performance are the keys to the success of filtration process.

Fruit Wine Filtration

Good fruit wine, wine should be clear, transparent, no sediment and suspended matter, give a person a sense of clarity, color is also the juice of the special pigment and aroma. The membrane filtration process is carried out at room temperature, and the pure physical method is used for filtration. There is no qualitative change in the separation process, and bacteria, impurities, extracts and harmful substances can be removed from the process. The fine degree of filtration determines the quality of the liquor. Darlly Filtration helps customers to find the most suitable filtration solution through verification and other tests conducted by its laboratories. Fruit wine is fermented by yeast into alcohol with the sugar of the fruit itself. It has pure, elegant, pleasant, harmonious aroma and wine. It is sweet and sour and full bodied.There are many kinds of fruits in Our country, many fruits can brew fruit wine, especially plums, apples, kiwifruit, bayberries and other varieties in the wine brewing accounted for a larger proportion. At present, commercial production of a wide variety of wine, according to brewing methods and product characteristics, divided into fermentation wine, distilled wine, prepared wine, sparkling wine.Generally, certain amount of SO2 and pectinase powder should be added in time when apple and other fruit juices enter the fermentation tank, and separation should be carried out before fermentation occurs, so as to reduce the content of impurities in fruit juice to the minimum level, which can avoid the influence of impurities on the taste quality of fruit juice.

Packing Water Filtration

Water -- an indispensable nutrient for human beings, water in reality is undrinkable due to various external factors. In order to meet healthy drinking standards, water needs to be extremely filtration intensive while retaining beneficial mineral elements. Water quality varies greatly from region to region. Darlly Filtration provides efficient and economical solutions based on field water quality to better meet the needs of enterprise reality and development. In China, the main packaging aquatic products on the market: drinking pure water, distilled water, drinking natural spring water, drinking mineral water, drinking natural water.The process of each product is slightly different. The production process of packaging drinking water, especially drinking mineral water, is relatively simple. In order to ensure the mineral content, reverse osmosis technology is generally not used.GB 19298-2014 and GB8537-2018, the national Food Safety Standard for Drinking Natural Mineral Water, are the main standards in the industry, which have strict requirements on microorganisms and added indexes of Pseudomonas Aeruginosa.Pseudomonas aeruginosa may enter the finished water through a defective filter, so it is very important to select a high efficient and reliable terminal sterilizing filter to ensure the quality of finished water.For the filter element with microorganism level removed, the bacteria challenge test must be carried out with the international standard bacteria species according to the international standard method and procedure, and the integrity test standard value of the filter element in use must be determined. Darlly Filtration laboratory has a strict verification test to ensure that the filter element will completely retain the harmful microorganisms such as pseudomonas aeruginosa in the final filtration.